Airlift Separator Featured in When Magazine, June 2011 Issue:

From the article:

Airlift Separator

Foley said that one of the things that has helped his business to grow in this direction is his use of an Airlift Separator. “With the amount of plastics that there are in food and wood waste, I couldn’t do what I do without this piece of equipment,” he said. “Even though we work diligently to train the folks that bring us yard waste and food waste, for composting, they often will forget and leave pieces of plastic material – bags, wrappers, and other light-weight plastic – in with what they drop off. Once we have composted the material, we are able to screen it and remove the plastic with the Airlift Separator. That gives us the high quality material that we need to make our compost and biosoils.”

“Airlift Separator really does work!”

When it comes to the problems that mulch and compost producers have with residual plastic material that always seems to make its way into yard waste and food waste feed stock. Ned Foley’s situation was similar to every else’s. “We are always looking for ways to improve the quality of our compost,” said Foley. “For our compost and biosoils mixes, we need to have as little plastic in the final product as possible. It seems as though there are always some wrappers or plastic bags that make it into the compost pile. So, when we looked for a way to get rid of that unwanted material, that was when a demonstration of the Airlift Separator convinced me that was the answer to our problem.”

Foley said that he purchased the AL200D, diesel powered unit approximately one year ago. Since then, whenever he is screening material that might contain plastics and other unwanted light-weight material, he attaches the Airlift Separator, and high quality compost and mulch is the result.

“We take in a lot of yard and food waste, and even though we are always trying to train our suppliers, it seems like there is always some unwanted plastic in the load,” he said. “After we had seen a demonstration by Brendon Fox of MCB that Jimmy Smith from [Airlift Separator] had arranged, we knew that this was a tool that could really help us. We found that when we are using the [Airlift Separator], it removes 80 to 90 percent of the plastic in the material. We are extremely pleased with how this unit works.”

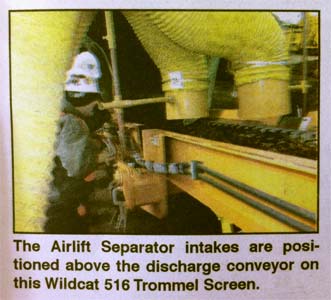

The Airlift Separator acts like a large vacuum cleaner that typically is mounted on the discharge conveyor of a trommel or as in Foley’s case, an Aggregates Equipment screening unit. For more thorough cleaning a larger, dual fan unit, the AL400D is available which can be used clean both the fines and overs on screener’s conveyors if that is the desired configuration. In any case, the Airlift Separator removes plastics and other lightweight material from compost and mulch without slowing down production. A look in Foley’s discharge bin gives an idea of the kind of unwanted material this system can remove.

“We couldn’t do the kind of composting that we do without the Airlift Separator,” said Foley. “You can just watch the material as it passes under the hose. The plastic just seems to jump off the conveyor while the mulch or compost continues on its way to the stockpile. This machine really works!” For more information on the Airlift Separator, contact Jimmy Smith at (888) 345-9085 or visit their website at airliftseparator.com

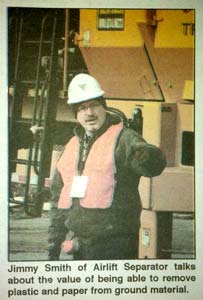

[From the July 2011 issue of When Magazine] At a demonstration of an Airlift Separator, Jimmy Smith showed how mulch laced with unwanted plastic and paper can be screened with ease using a model AL400D Diesel Powered unit mounted to a Wildcat 516 Trommel Screen. Smith explained that recyclers and composters are always looking for ways to remove the unwanted plastic and paper that somehow always seems to make its way into mulch. For recyclers who are looking to produce a value added product such as composted soils or high quality, plastic-free mulch. The Airlift Separator is the ideal tool for the job. More importantly, the Airlift Separator comes in four configurations that include diesel, hydraulic and electric powered models in two sizes.Smith can be reached at 888 345-9085